[ad_1]

The best of these pieces, which can take 8 days to make, contains over 8,000 stitches, and is made from the finest Italian wool

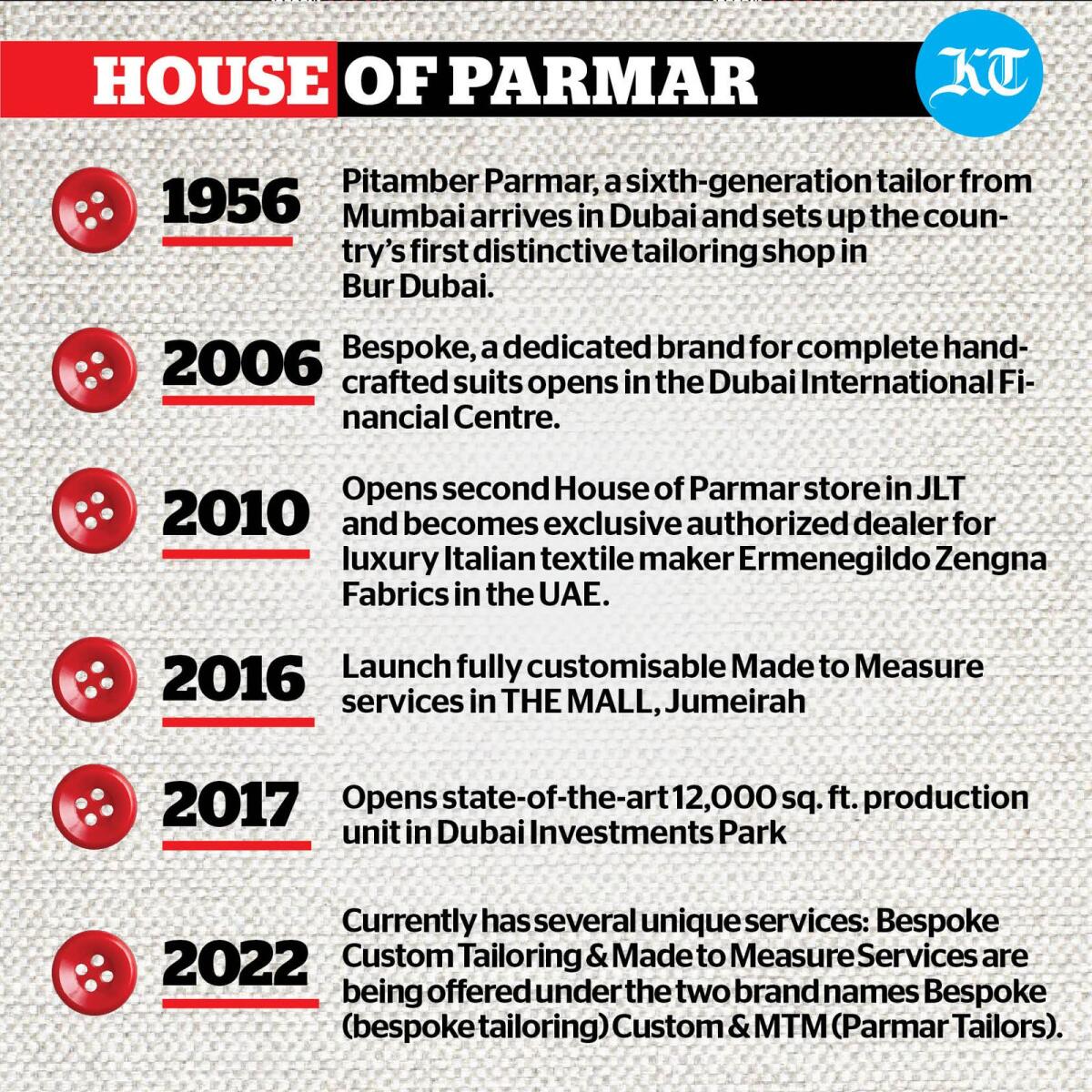

When Pitamber Parmar left everything behind in Mumbai in 1956 and headed to Dubai for an exploration trip, little did he know it was just the beginning of an extraordinary journey.

At a time when the emirate did not have proper running water or a reliable lighting system, Parmar, a talented and ambitious young man, opened a humble tailor shop in Bur Dubai.

Photo: Provided

In 1986, with his youngest son, Prakash, he began laying the groundwork for what would become a bespoke clothing empire the country had never seen before.

In addition to making history as the first tailor to set up shop in Dubai, Parmar broke new ground by using polyester thread for sewing, going beyond cotton varieties.

Fast forward 66 years, and today’s House of Parmar caters to the country’s fashion-conscious men of all walks of life, offering tailored suits beautifully crafted to reflect an individual’s personality and style.

“We’re who we are because we’ve been working hard,” says Prakash, who learned to be a tailor for eight years before his father taught him to be a master tailor.

What is the process of making a custom suit?

From the very beginning, Parmars has stayed true to its principles as artisans of handmade garments.

A visit to DIFC’s Bespoke tailoring department will open up a world of possibilities for beginners as they will be confronted with a combination of samples, garment designs, illustrations, accessories, palettes, fabrics and skilled tailors.

A tailored suit is all about the perfect fit and may require multiple tries at different stages of tailoring. Bespoke’s skilled artisans build on each fitting, achieving a more precise fit in the process.

Regardless of the style, fabric or craftsmanship complexity of each suit, there are no limits to choice, as master tailors follow a specific method needed to create the perfect look for the wearer. The attention to every detail is accompanied by religious fervor, and even the buttonholes and buttons are meticulously sewn by hand.

Six Decades of Suit Making

Away from Savile Row, the iconic Mayfair fashion street in central London, talented tailors from India have been tailoring suits for stylish gentlemen in the UAE.

Since clients may not have the time to research the items in the store or current trends and popular classic styles, Parmar’s skilled master tailors invest their time in crafting the suits clients are looking for. Fashionista Okey Onyegbule is one such happy customer:

The best of these pieces, which can take 8 days to make, contains over 8,000 stitches and is made from the finest Italian wool.

Digitization of suit making

By storing customer data, measurement data and history in a complex computer-aided design (CAD) program, Parma Bespoke creates an easy, trouble-free tailoring experience, reducing consultation time and helping to make customizations faster clothing.

Every tiny detail and measurement is entered into CAD as it enters the custom production chain. In each section, the craftsman only focuses on his area of expertise and then passes it on to the next section.

It’s a very hands-on operation under the watchful eye of Prakash, who believes every man should have a good suit to reflect his personality. All along, he diligently oversees the management of the work and craftsmanship.

“It’s all about making a strong statement,” Prakash explained. “If you’re wearing a well-made suit, people will see you differently. They’ll take you more seriously.”

[ad_2]

Source link