[ad_1]

The finest of these pieces take 8 days to complete, contain over 8,000 stitches, and are crafted from the finest Italian wool

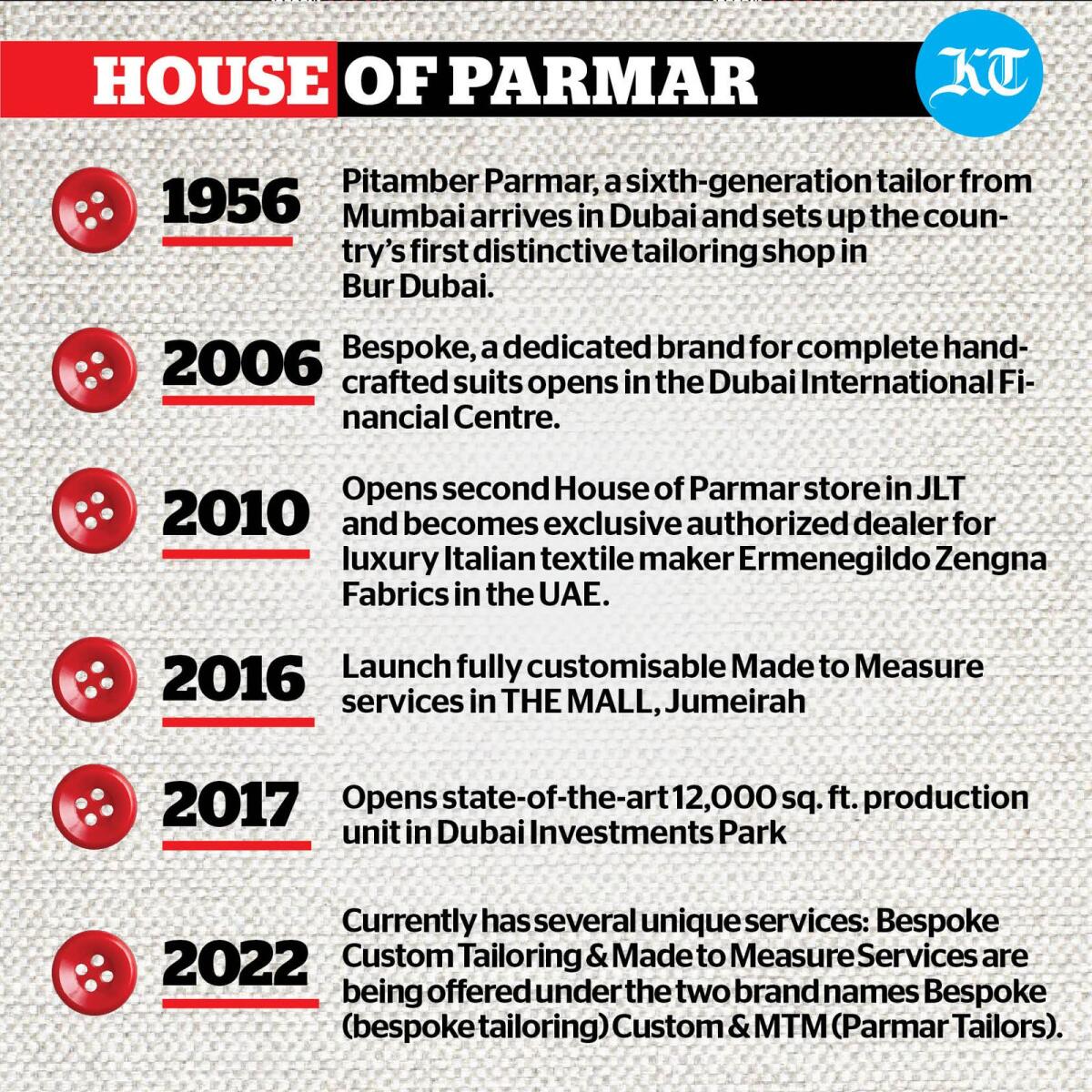

When Pitamber Parmar left Mumbai behind in 1956 to embark on a voyage of discovery in Dubai, little did he know it was just the beginning of an extraordinary journey.

At a time when the emirate had no proper running water or a reliable lighting system, Palma, a talented and ambitious young man, opened a humble tailor shop in Bur Dubai.

Photo: Supplied

In 1986, he took his youngest son, Prakash, under his wing and began laying the foundations of the country’s yet-to-be-made tailoring empire.

In addition to making history by being the first tailor to open a shop in Dubai, Parmar also broke new ground when he introduced polyester thread for sewing, which outperformed cotton varieties.

Fast forward 66 years, and today Casa de Palma caters to the country’s fashion-conscious crossover male, offering well-crafted bespoke suits that reflect an individual’s personality and style.

“We became who we are today because of the journey we took,” says Prakash, who studied tailoring for eight years before his father taught him the craft to become a master tailor.

What is the process of making a custom suit?

From the beginning, Parmars has adhered to the principle of being artisans who make garments by hand.

A visit to DIFC’s Bespoke tailoring department will open up a world of possibilities for the layman as they are confronted with a combination of samples, garment designs, illustrations, accessories, color palettes, fabrics and skilled tailoring.

A bespoke suit is all about the perfect fit and may require several fittings at different stages of tailoring. Bespoke’s skilled craftsmen create it on a fitting-by-fit basis, achieving a more precise fit in the process.

No matter how intricate the style, fabric or workmanship of each suit, the options are unlimited, as the tailor follows a specific method and needs to create the perfect fit for the wearer. Every attention to detail is accompanied by religious fervor, even the buttonholes and buttons are meticulously sewn by hand.

Six years of suit making

Away from Savile Row in Mayfair, the iconic fashion street in central London, talented tailors from India have been creating bespoke suits for fashion-conscious gentlemen in the UAE.

As customers may not have the time to research what’s in store or what the current trends and classic styles are, Parmar’s skilled master tailors dedicate time to creating the suit the customer is looking for. Fashionista Okey Onyegbule is one such happy customer:

The finest of these pieces take eight days to complete, contain over 8,000 stitches, and are made from the finest Italian wool.

The Digitization of Suit Making

By storing customer data, measurements and history in a sophisticated computer-aided design (CAD) program, Parma Bespoke creates a hassle-free cutting experience, reduces consultation time and helps make custom garments faster.

Every minute detail and measurement is entered into CAD as it enters the bespoke production chain. In each section, the craftsman focuses only on his field of expertise before passing it on to the next section.

It was a very hands-on operation under the watchful eye of Prakash, who believes every man should have a good suit that reflects his personality. All the while, he tirelessly oversaw the management of the work and craftsmanship.

“It’s all about making a strong statement,” Prakash explains. “If you wear a well-made suit, people look at you differently. They take you more seriously.”

[ad_2]

Source link